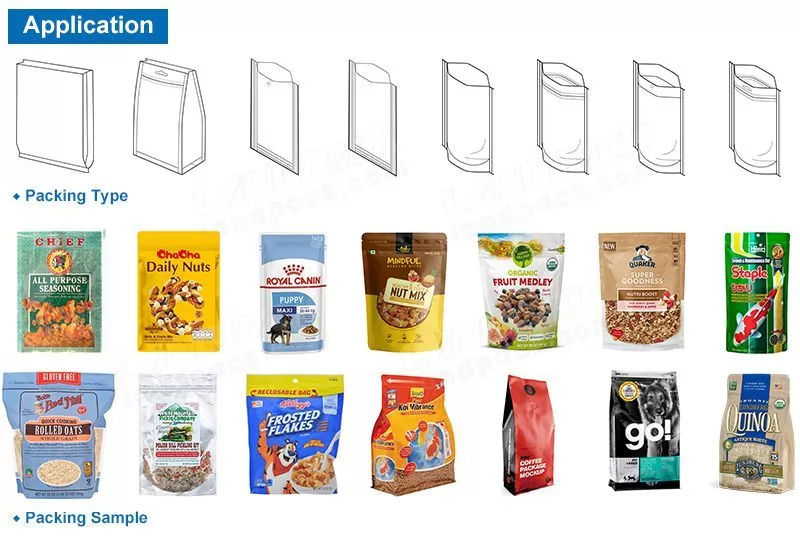

Application:

In recent years, Premade Pouch packaging machine in the packaging market gradually occupies a dominant position. Many advantages of Premade Pouch, such as its excellent appearance, portable opening, and user-friendly sealing method, make it the first choice of consumers. Premade pouch provides manufacturers with more packaging options, material handling strategies, and fully automated solutions.

Automatic Grain Granule Premade Stand Up Pouch Filling And Sealing Machine can auto finish material feeding, weighing, premade pouch pick-up, open, fill and seal, etc. Premade pouches can be flat pouches, gusset pouches, side seal bags, fin seal bags, block bottom bags, zip-lock recloseable bags, or stand-up pouches without zipper.

Suitable for small granule material, such as crystal monosodium glutamate, seasoning, washing powder, pesticides, chemicals, sugar, feed and other small granule material automatic packing.

| Packaging Material & Bag Style: |

|

Feature:

Basic Functions:

1.The machine stops running when the safety key interlock switch is pulled out;

2.No bag prompting function;

3.Self-diagnosis function of open the bag failed (The bag can be reused); In that case, the machine will not fill and seal, it will re-take the bag;

4.Positioning (anti-dropping) function of hopper;

5.Warning function of cartridge heater fault ;

6. Warning function of cylinder fault.

7.Warning function which air pressure is not up to standard.

Performance Features:

1.Easy to operate and easy to replace the bag / The machine is suitable for a variety of bag types;

2.Low maintenance cost / Modular replacement of the parts;

3.Certificate of Conformity.

Parameter:

Model: LD-200AX

Bag Material: Multilayer Composite Premade Bag (e.g.: PET/PE)

Bag Type: 3 Side Seal Bag, Stand-up Bag"

Upgradable Bag Type: N/A

Size Range: 70mm≤W≤150mm, 100mm≤L≤200mm"

Speed: 0~26bags/min

Sealing Type: Straight grain, pitch is 1mm (Optional reticulate)

Sealing Width: 10mm (5--20mm can be customized)

Voltage: 220V, Single-phase, 50/60HZ, 1KW

Air Pressure: 0.65Mpa

Air Consumption: 0.2m³/min (Standard machine, no additional function)

Body Dimension: 1080*535*1010mm

Packing Dimension: 1240*670*1320mm (Export non-fumigation wooden case)

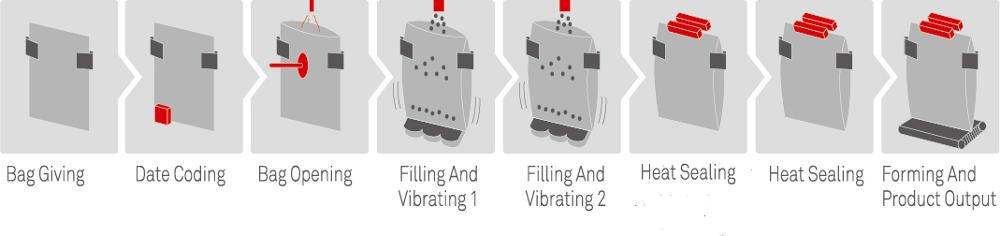

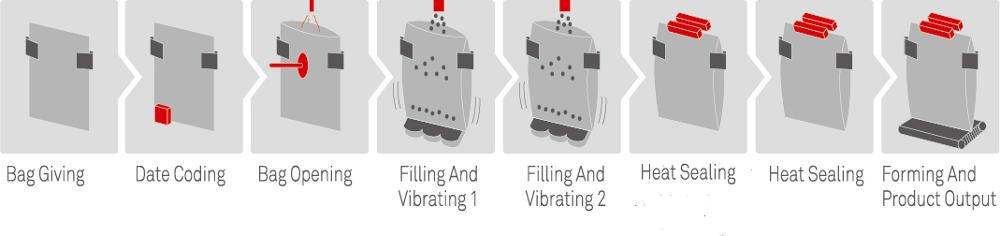

Work Process:

1. Bag giving--Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there are a mechanical arm with two vacuum caps will take the bag up and then transmit it to the mechanical gripper on the rotary table.

2. Date coding--According to the actual production and packaging needs, different types of coding machines are configured to print the date and batch number on the packaging bag.

3. Bag opening--While the suction cup opens the opening of the packaging bag, air is sprayed from the upper nozzle to blow open the bottom of the packaging bag, the packaging bag support plate is inserted into the opening of the packaging bag, and the packaging bag enters the next station.

After inserting the bag support plate into the bag opening, the detection of whether there is a packaging bag and whether the opening of the bag is opened is completed. If there is no packaging bag or there is no opening to open the packaging bag, the next station will not feed.

4. Filling and vibrating 1--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

5. Filling and vibrating 2--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

6. Product settling after filling by vibrating

7. Heat sealing 1--To seal the pouch or bag mouth with a couple of heat sealing air bar, the sealing pattern you can option, net or straight lines.

8. Heat sealing 2--To make the sealing stable and preventing from wrinkling with a couple of cold press, then output the finished production automatically.

9. Forming and product output

Video: