Introducing our high-performance Ketchup Bottle Filling and Capping Machine, specifically designed for packaging various liquid, fluid, and paste materials such as ketchup, tomato sauce, mayonnaise, chili sauce, jam, paste, juice, edible oil, sauce, honey, and even daily necessities and medicinal products.

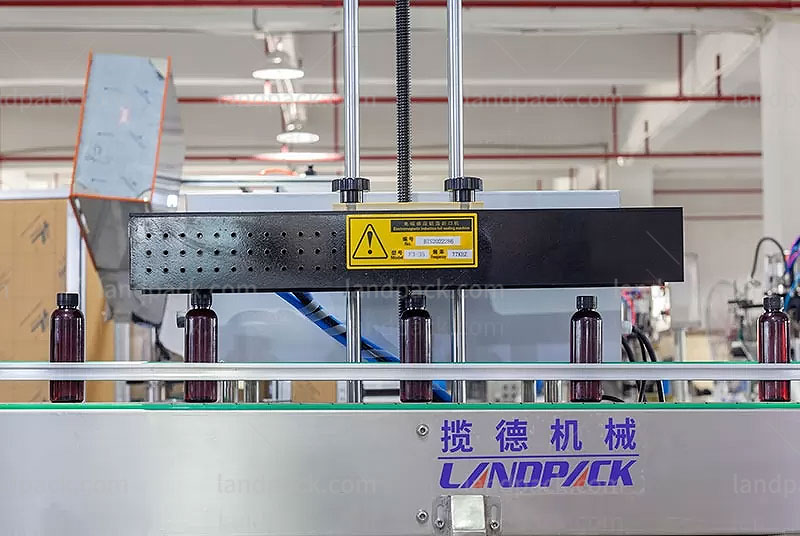

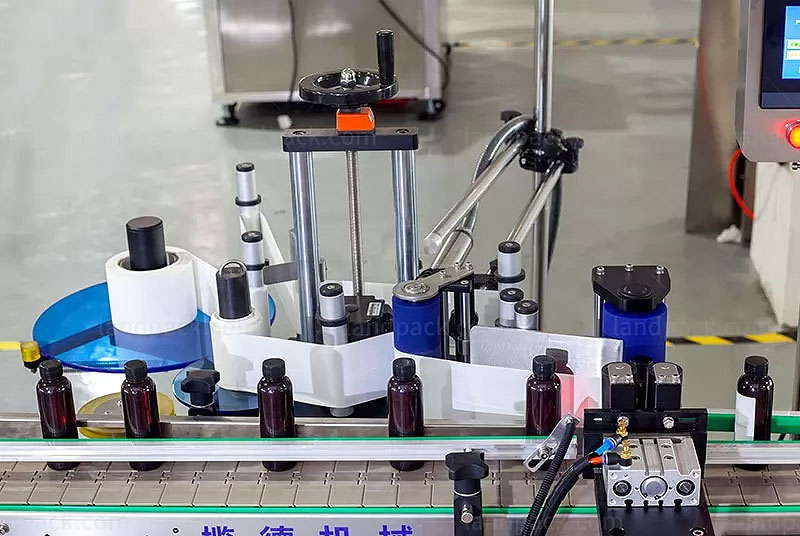

Our Ketchup Bottle Filling and Capping Machine guarantees exceptional performance and versatility, accommodating a wide range of products with varying consistencies. Its advanced technology ensures accurate measurements and consistent filling, resulting in perfectly sealed bottles every time. Whether you're packaging condiments, sauces, oils, or even pharmaceuticals, this machine provides the reliability and efficiency needed to streamline your production line.

With user-friendly controls and easy adjustments, our machine offers seamless operation and minimal downtime. Its robust construction and reliable components ensure durability and longevity, reducing maintenance costs and enhancing productivity. The compact design saves valuable floor space, making it suitable for both small-scale and large-scale manufacturing environments.

|

Packaging Material:

|

|

|

|

|

|

|

|

Milk

|

Juice

|

Honey

|

Oil

|

Salad dressing

|

Sauce

|

|

Bag Style:

|

|