Designed to handle a wide range of granular and solid materials such as marijuana, cannabis, beans, nuts, dry fruits, candy, cereal, chocolate, biscuits, peanuts, capsules, seeds, chemicals, sugar, and more, our cutting-edge equipment is perfect for streamlining your production process.

With LandPack Automatic Cannabis Bottles Weighing Filling Capping and Labeling Lines, you can effortlessly fill various types of containers, including bottles, plastic cans, glass cans, tinplate cans, cartons, and more. Our advanced technology ensures accurate weighing, precise filling, and secure capping, guaranteeing the integrity and quality of your products.

In addition, our lines are equipped with high-speed labeling capabilities, allowing you to efficiently apply custom labels to your containers. This not only enhances brand visibility but also ensures compliance with industry regulations.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

| Packaging Material: |

|

|

|

|

|

|

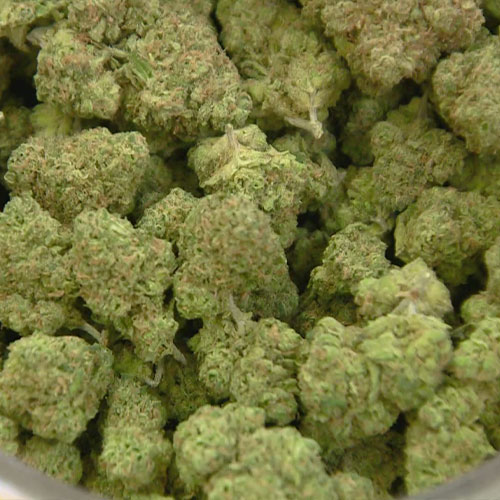

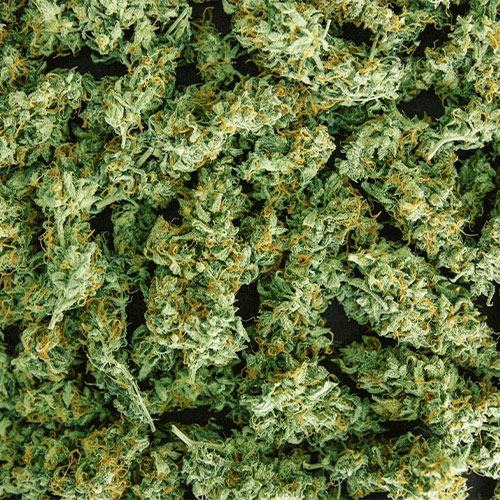

| Marijuana |

Marijuana |

Weed |

Cannabis |

Hemp |

Marihuana |

| Bag Style: |

|