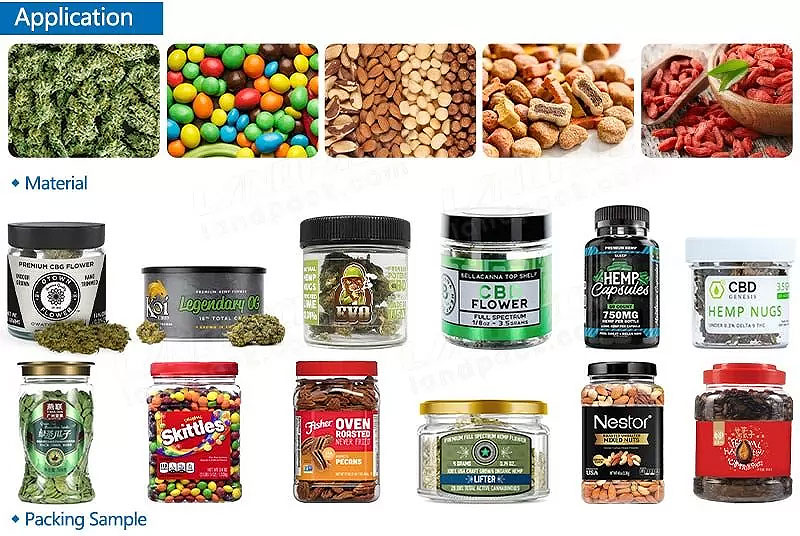

Full automatic granule bottles weighing filling capping and labeling lines, Scope of application: granular and solid materials such as marijuana, cannabis, weed, hemp, beans, nuts, dry fruits, candy, cereal, chocolate, biscuit, peanut, capsule, seeds, chemicals, sugar, etc.

Filling Containers:

Bottles, plastic cans, glass cans, tinplate cans, cartons, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

| Packaging Material: |

|

|

|

|

|

|

| Marijuana |

Marijuana |

Weed |

Cannabis |

Hemp |

Marihuana |

| Bag Style: |

|

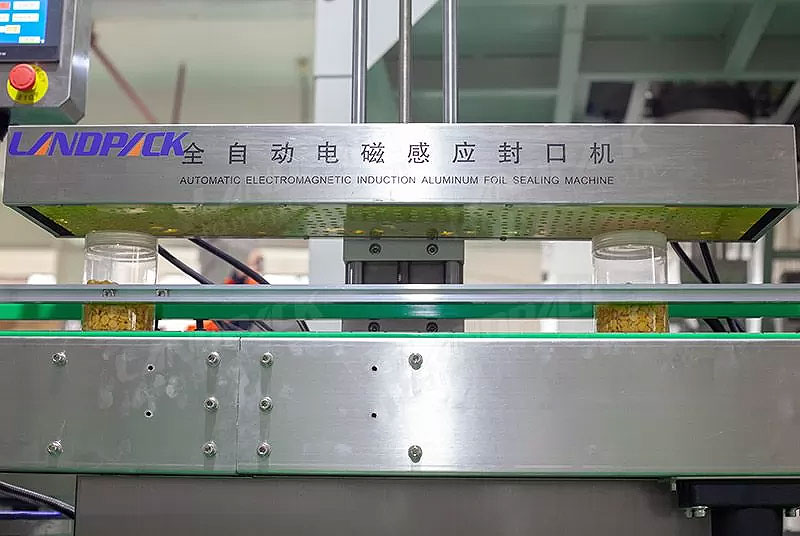

1. This production line adopts automation technology, with imported PLC, detection photoelectric eyes, frequency converters, and pneumatic components. It features high efficiency, intelligence, wide adaptability, and good stability, which has won high praise from users.

2. The production line is composed of automatic bottle feeding, linear weighing filling machine, four-wheel rotating capping machine, wafer locating rotary bottle labeling machine, and collecting platform to form a fully automated production line.

3. The entire frame of the production line is made of SUS304 material, with a unique and beautiful appearance.

4. The production line runs stably with low noise and easy maintenance, fully complying with GMP certification requirements, and is widely used in the pharmaceutical and food industries.

5. The production line uses an imported PLC and 7-inch touch screen HMI for parameterized control, making operation simple and efficient.

6. This advanced production line can be customized according to customers' different requirements, producing equipment that fully meets their needs.