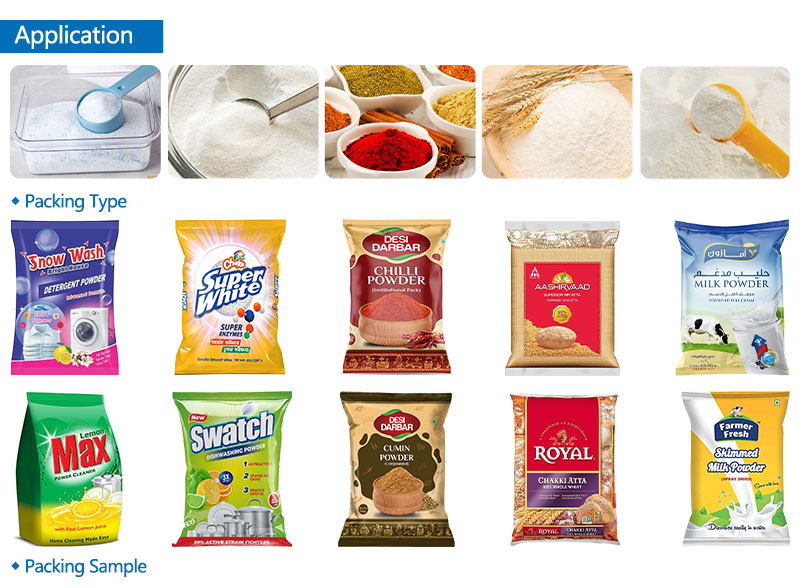

It's suitable for automatic packing detergent powder, washing powder, bleaching powder, coffee powder, spice powder, milk powder, flour, fruit powder, seasoning, chemical medical powder, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

|

Packaging Material & Bag Style:

|

|

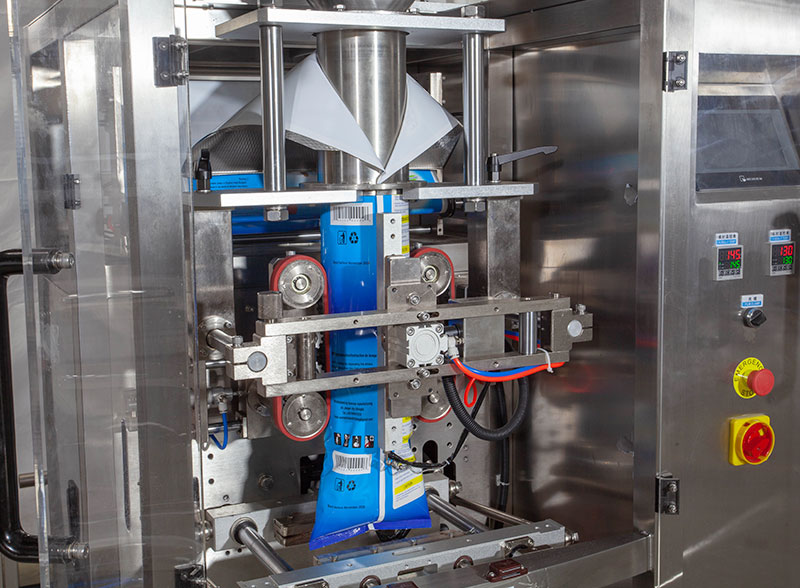

1. The machine's compact structure efficiently transports materials, saving space in your production area.

2. Equipped with a renowned PLC (Programmable Logic Controller), the machine's color touchscreen interface ensures intuitive and efficient operation.

3. The use of imported components enhances performance. The color standard sensor accurately positions the film, resulting in beautiful packaging.

4. The machine can produce various bag types, including pillow bags, pocket bags, hole bags, and joint bags, catering to different packaging needs.

5. Material contact parts (such as storage hoppers, hoppers, vibration plates, and weighing hoppers) are designed for fast disassembly, easy cleaning, and maintenance.

6. The touchscreen interface, combined with stable and reliable PLC control, streamlines the entire packaging process. Bag-making, metering, filling, sealing, coding, and bag-cutting occur seamlessly.

7. The adoption of volume-measuring cups ensures accurate and cost-effective filling.

Workflow:

1. Intelligent control screen, one-click start

2. Z-type material conveyor loading

3. Volume measuring cup measurement

4. Automatic filling

5. Bag making and sealing