This automatic counting packing machine is suitable for different kinds of fastener

- Disposable tableware (Disposable cutlery, cutlery, aviation cutlery set, etc.)

- Furniture parts (Fittings, Fastener, Hinge, Lock, etc.)

- Electronic machinery and appliance spare parts (Mobile Phone Screw, Cable Clip, etc.)

- Fastener (Screw, Bolt, Nut, Washer, Nail, Small Hardware, O-Rings, etc.)

- Plastic, pipe fittings (Pipe, Joint, etc.)

- Clothes parts (Button, Slider, etc.)

- Toys (Toy Building Brick, Dice, etc.)

- Stationery (Mark, Pen, Clip, etc.)

- Other regular shape parts

|

Packaging Material & Bag Style:

|

|

1. This system is specifically designed to efficiently handle bulk hardware products.

2. The system automatically tallies the items as they’re packaged. This not only saves time but also reduces the chances of human error.

3. If there’s any deviation from the intended packaging, it corrects it on the fly.

4. The stainless steel frame ensures longevity and easy cleaning. Plus, it looks sleek in any production environment.

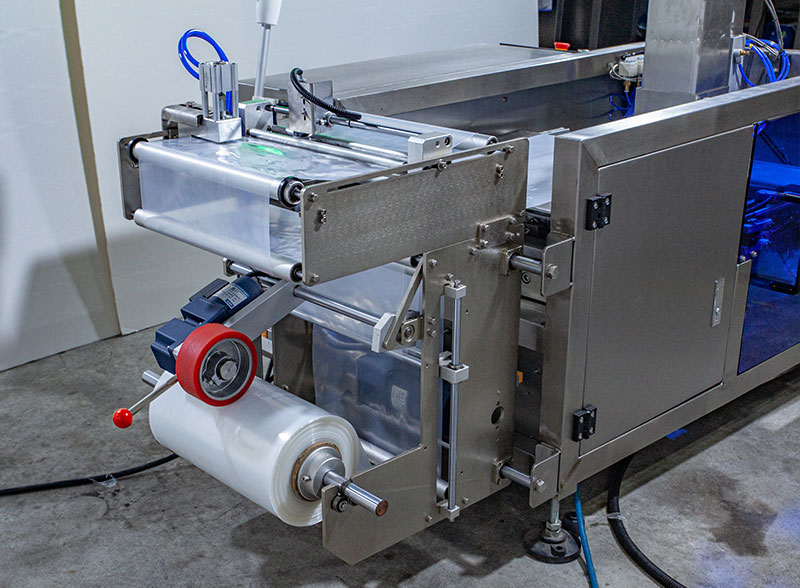

5. This system uses tube film directly to create custom bags for your hardware products. It’s efficient and minimizes waste.

6. The system self-diagnoses issues and alerts operators promptly. Time saved, productivity maintained.

7. The HMI allows operators to adjust parameters easily.

8. The programmable logic controller (PLC) ensures consistent and reliable seals, keeping your hardware secure.

9. The straightforward transmission system is easy to maintain, minimizing downtime.

10. Customize the bag width to accommodate different hardware sizes.

11. It detects and prevents empty bags from being sealed, ensuring every package contains the intended items.

Workflow:

1. Counting bowls count the fasteners

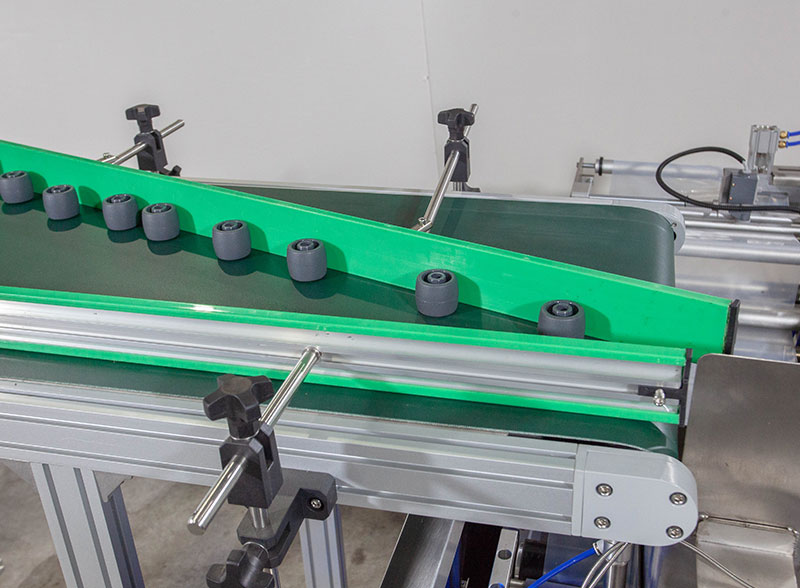

2. The worker put the material on the chain

3. The chain container brings the fasteners to pack

4. Form the bag by roll film

5. Output the finished packages