Application:

Automatic Multitrack Olive Oil Sachet Pouch Counting Into Bag Packaging System is suitable for kinds of liquid products, such as olive oil, cooking oil, shower gel, fruit juice, honey, milk, mouthwash, sauce, jam, jelly, etc.

Packaging Line Composition:

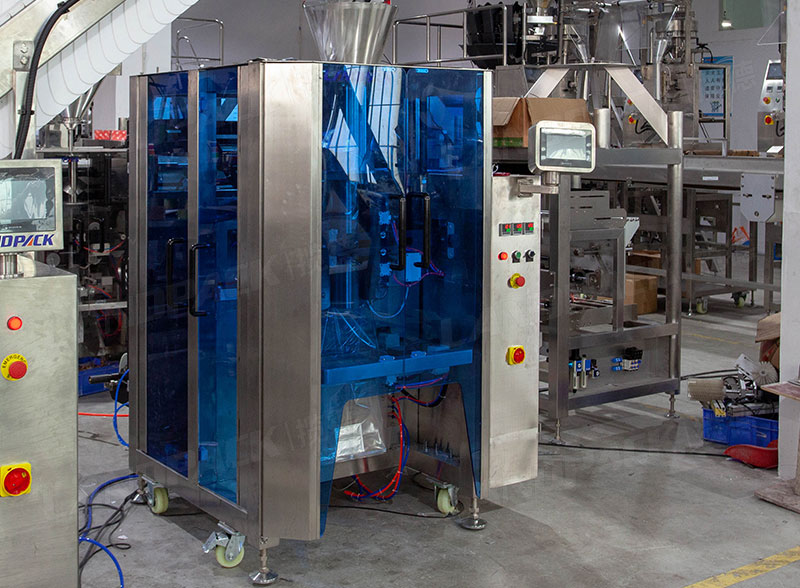

This sachet packaging and bag-in-bag machine system consists of multi-lane sachet pack liquid packaging machine, counting machine and vertical form filling sealing machine. It can realize sachet packed packaging into a bag.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

|

Bag Style:

|

|

1. 2 liquid multi-channel packaging machines to improve your production and packaging efficiency.

2. The conveyor outlet is equipped with a counting sensor and collection device to collect the target number of small bags and discharge them into the chain conveyor.

3. The imported counting sensor has a high sensitivity to ensure the correct counting target amount.

4. A servo motor drives the inclined conveyor. No movement is allowed without materials.