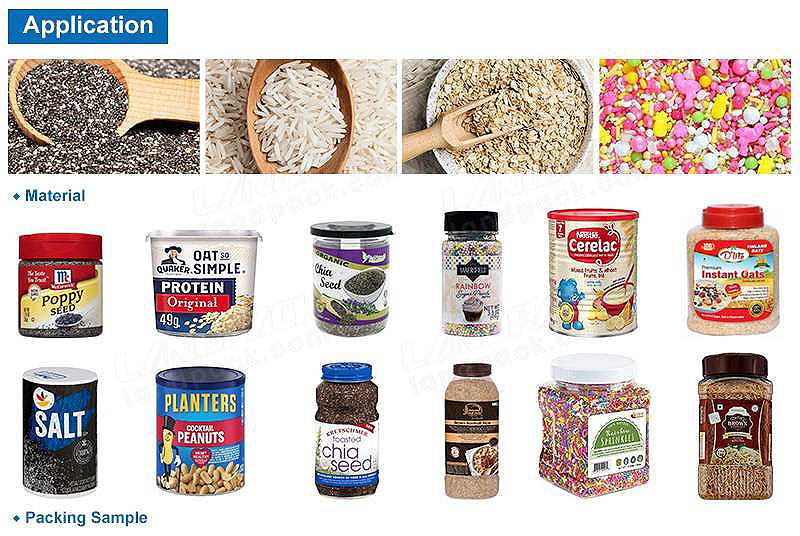

Automatic nuts bottle weighing filling capping and sealing machine, Scope of application: granular and solid materials such as nuts, beans, peanuts, snacks, cashew, sugar, rice, beans, condiments, washing powder, feed, desiccant, plastic pellets, grains, etc.

Filling Containers:

Bottles; plastic cans; glass cans; tinplate cans; cartons, etc.

Kindly Reminder:

Please tell us the following information when you send us an inquiry. Based on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Filling Range

3. Bottles/Cans/Tins material

4. Bottles/Cans/Tins dimension

| Packaging Material & Packing Style: |

|

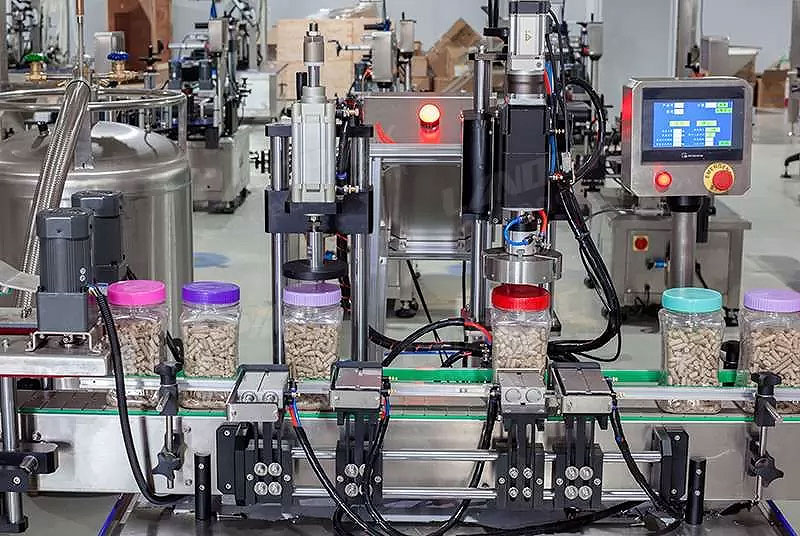

1. This production line adopts automation technology, imported PLC, imported inspection light eye, frequency converter and other electrical appliances, and pneumatic components. It has the characteristics of high efficiency, intelligence, wide adaptability, good stability, etc. and is well-received by users;

2. This line uses automatic bottle feeding, linear scale filling machine, four-wheel capping machine, wafer positioning round bottle labeling machine, and collection platform to form a fully automated production line;

3. The machine frame of the whole line is made of SUS304 material, with a unique and beautiful appearance;

4. The production line has stable operation, low noise, convenient maintenance, fully meets the requirements of GMP certification, and is widely used in medicine, food, and other industries;

5. Imported PLC and 7-inch touch screen man-machine interface, production parameterized control, simple operation;

6. This kind of production line is relatively advanced and can be improved according to the different requirements of customers, and can be made into equipment that fully meets customers' needs;

7. Equipped with nitrogen filling function to extend the shelf life of packaged products.