LandPack LD-8200L/LD-8250L Automatic Rotary Liquid Spout Pouch Premade Pouch Filling Machine is the perfect solution for packaging liquid and thick liquid products such as detergent, fruit juice, wine, soy sauce, vinegar, drinks, chili sauce, tomato sauce, peanut butter, jam, bean sauce, and more.

This versatile machine is compatible with various types of premade pouches including spout pouches, 3-side sealing bags, 4-side sealing bags, stand-up bags, handbags, zipper bags, compound bags, and more.

With its advanced technology and efficient operation, this filling machine is ideal for any industry looking to enhance its packaging process.

| Packaging Material: |

|

|

|

|

|

|

| Milk |

Juice |

Honey |

Oil |

Salad dressing |

Sauce |

| Bag Style: |

|

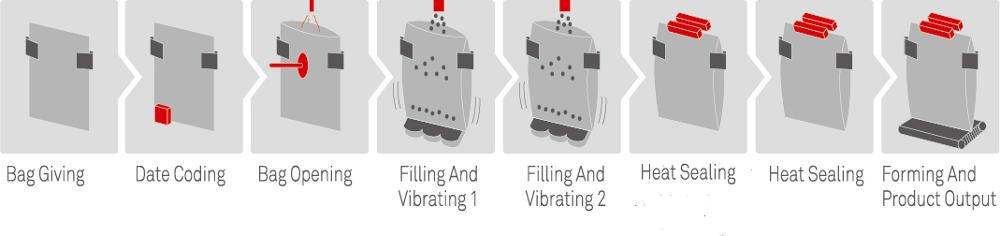

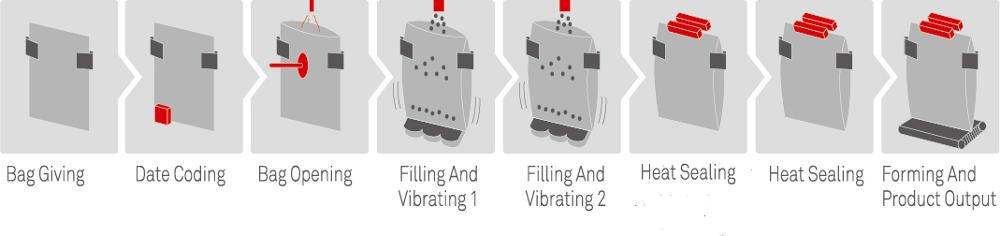

Bag giving > Date coding> Bag opening > Filling and vibrating 1 > Filling and vibrating 2 > Product settling after filling by vibrating> Heat sealing> Forming and product output