Application:

Full automatic bottles/ cans granule weighing filling capping and labeling machine suitable for granular and solid materials such as nuts, beans, peanuts, snacks, cashew, sugar, rice, beans, condiments, washing powder, feed, desiccants, plastic pellets, grains, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

| Packaging Material & Bottles Style: |

|

Feature:

1. This production line adopts automation technology, imported PLC, imported inspection light eye, frequency converter and other electrical appliances, and pneumatic components. It has the characteristics of high efficiency, intelligence, wide adaptability, good stability, etc., and is well-received by users;

2. This line uses automatic bottle feeding, linear scale filling machine, four-wheel capping machine, wafer positioning round bottle labeling machine, and collection platform to form a fully automated production line;

3. The machine frame of the whole line is made of SUS304 material, with a unique and beautiful appearance;

4. The production line has stable operation, low noise, convenient maintenance, fully meets the requirements of GMP certification, and is widely used in medicine, food, and other industries;

5. Imported PLC and 7-inch touch screen man-machine interface, production parameterized control, simple operation;

6. This kind of production line is relatively advanced and can be improved according to the different requirements of customers, and can be made into equipment that fully meets the needs of customers.

Parameter:

| Model |

LFZX-SC-10 |

| Filling Speed |

10-20 bottles/min |

| Bottle diameter |

Φ30mm-Φ135mm(customizable) |

| Bottle height |

40mm-200mm(customizable) |

| Control system |

PLC |

| Total lines power |

6.8KW |

| Power supply |

220V, 50Hz |

| Airconsumption |

0.6 m³/min |

| Equipment material |

304 stainless steel |

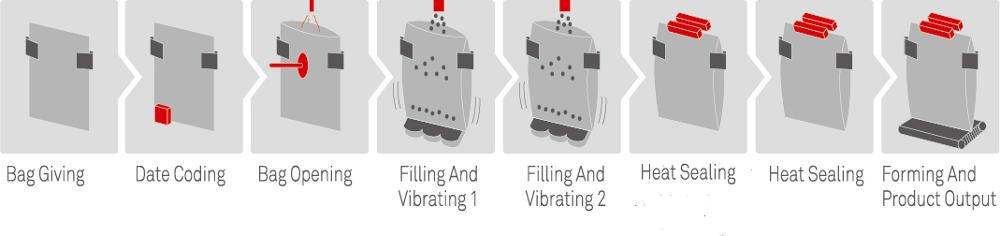

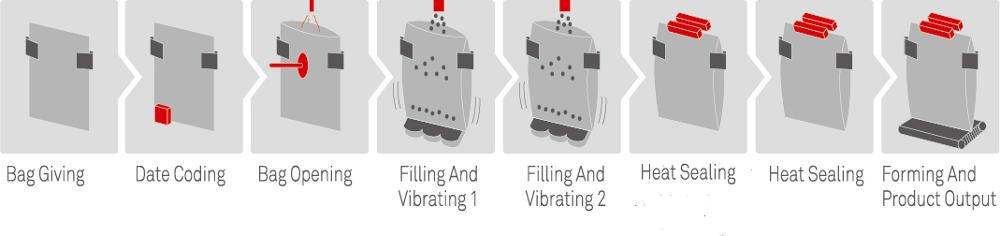

Work Process:

1. Bag giving--Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there is a mechanical arm with two vacuum caps will take the bag up and then transmit it to the mechanical gripper on the rotary table.

2. Date coding--According to the actual production and packaging needs, different types of coding machines are configured to print the date and batch number on the packaging bag.

3. Bag opening--While the suction cup opens the opening of the packaging bag, the air is sprayed from the upper nozzle to blow open the bottom of the packaging bag, the packaging bag support plate is inserted into the opening of the packaging bag, and the packaging bag enters the next station.

After inserting the bag support plate into the bag opening, the detection of whether there is a packaging bag and whether the opening of the bag is opened is completed. If there is no packaging bag or there is no opening to open the packaging bag, the next station will not feed.

4. Filling and vibrating 1--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

5. Filling and vibrating 2--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

6. Product settling after filling by vibrating

7. Heat sealing 1--To seal the pouch or bag mouth with a couple of heat sealing air bars, the sealing pattern you can option, net or straight lines.

8. Heat sealing 2--To make the sealing stable and preventing from wrinkling with a couple of cold presses, then output the finished production automatically.

9. Forming and product output

Video: