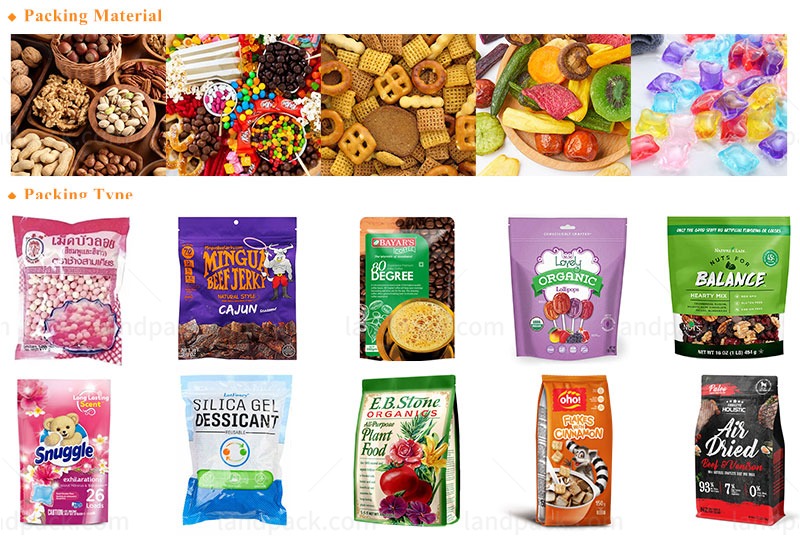

Application:

Landpack Premade Pouch Packing Machine, It is suitable for candy, hard nut, raisin, peanut, melon seedschips, chocolate, biscuit and other big grains or irregular shapeproducts auto weighing packing.

| Bag Style: |

|

Feature:

1. Wide applications: various states and natures of solid(granule);

2. A wide range of pouches: all kinds of pre-made pouches;

3. Easy to operate: PLC controller and HMI system makes easy operation;

4. Easy to adjust: change different pouches within 10 minutes;

5. High Automation: unmanned in weighing and packing process, machine alarm automatically when failure;

6. Perfect prevention system: when the bag is not opened or not opened completely, it will be non-filling and non-sealing, so the bags can be reused and the product is not wasted thus saving the production cost;

7. The product contact parts are adopted SUS304 to ensure sanitation and safety, and meet the GMP standard;

8. Imported engineer plastic bearings, no need to oil, no contamination;

9. Vacuum generator: low consumption, high efficiency, cleanness, and long useful life;

10. Pre-made bag packing: perfect sealing quality, upgrade the finished product;

11. The surface of the weigher is sprayed with Teflon to avoid sticking.

Parameter:

| Model |

LD-8200A/ 8240A/ 8300A |

| Packing material |

all types of heat sealable performed side seal bags, block bottom, bags, zip-lock recloseable bags, stand-up pouches with or without spouts, paper bags, flat pouches, stand-up pouches, zipper pouches, spout pouches, m gusset pouch, paper pouch, aluminum foil pouch, etc. |

| Size |

W: 70-200/L: 100-250 |

| Filling range |

10-1000g/20-2500g |

| Packing speed |

40-60 bags/min(speed is determined by the product filling quantity) |

| Average precision |

≤ ±1% |

| Total power |

2.5KW |

| Dimensions |

1900mm*1570mm*1700mm(L*W*H) |

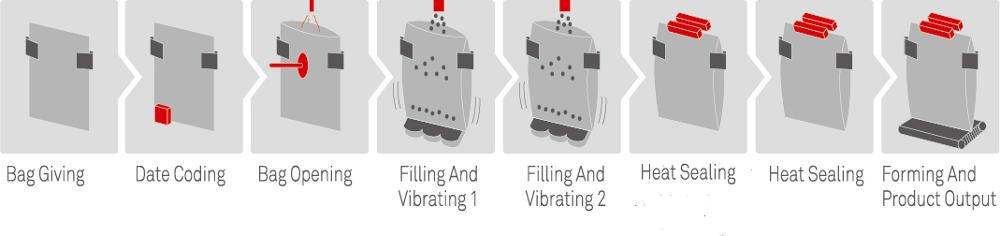

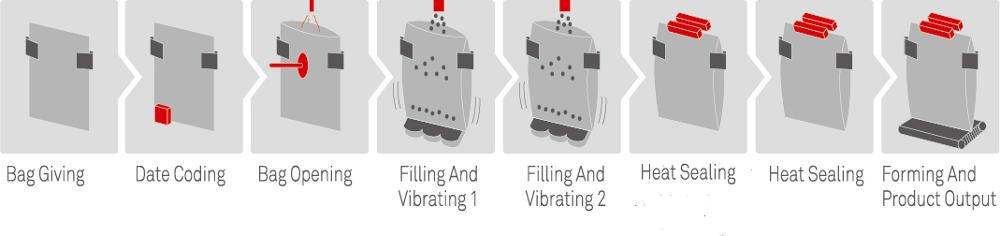

| Workflow |

giving bag→coding→opening→filling 1→filling 2→auxiliary→exhaust→heat sealing→forming and output product |

| Main standard parts |

1. Code printer 2. PLC control system 3. Bag opening device 4. Vibration device 5. Cylinder 6. Electromagnetic valve 7. Temperature controller 8. Vacuum pump 9. Inverter 10. Output system |

Work Process:

1. Bag giving--Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there are a mechanical arm with two vacuum caps will take the bag up and then transmit it to the mechanical gripper on the rotary table.

2. Date coding--According to the actual production and packaging needs, different types of coding machines are configured to print the date and batch number on the packaging bag.

3. Bag opening--While the suction cup opens the opening of the packaging bag, air is sprayed from the upper nozzle to blow open the bottom of the packaging bag, the packaging bag support plate is inserted into the opening of the packaging bag, and the packaging bag enters the next station.

After inserting the bag support plate into the bag opening, the detection of whether there is a packaging bag and whether the opening of the bag is opened is completed. If there is no packaging bag or there is no opening to open the packaging bag, the next station will not feed.

4. Filling and vibrating 1--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

5. Filling and vibrating 2--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

6. Product settling after filling by vibrating

7. Heat sealing 1--To seal the pouch or bag mouth with a couple of heat sealing air bar, the sealing pattern you can option, net or straight lines.

8. Heat sealing 2--To make the sealing stable and preventing from wrinkling with a couple of cold press, then output the finished production automatically.

9. Forming and product output

Video: