Multi lane liquid stick bag packing machine with counting cartoning line is suitable for kinds of liquid products, such as fruit juice, shampoo, shower gel, honey, milk, mouthwash, sauce, jam, jelly, etc.

Packaging Line Composition:

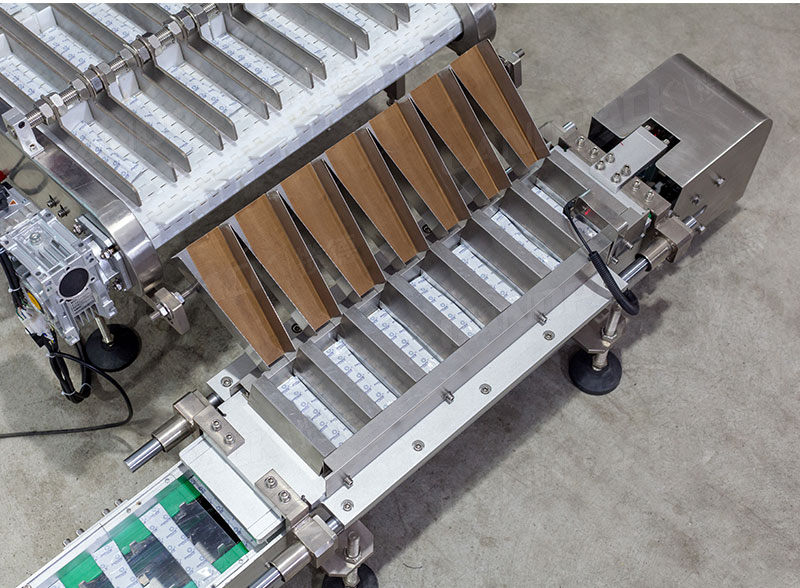

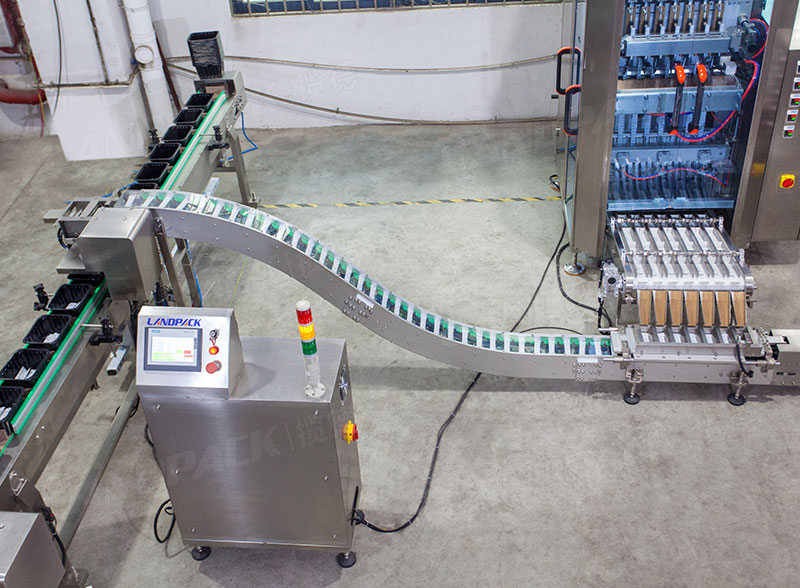

This stick packaging machine line consists of multi-lane stick pack liquid packaging machine, counting machine and stick pack into tray machine. It can realize stick-packed packaging into trays.

|

Packaging Material & Packaging Bag Style:

|

|

1. The machine ensures precise measurements, with an error margin controlled within ±0.5 ml. Additionally, its design facilitates easy cleaning.

2. If no material exists, the machine stops counting and triggers an alarm, enhancing efficiency and preventing errors.

3. The finished product conveyor track seamlessly connects to the ramp conveyor belt, ensuring accurate product placement.

4. The counting mechanism accommodates varying quantity requirements based on production needs.

5. The machine delivers beautifully packaged products with firm seals, enhancing product presentation and safety.

6. Adopting brand PLC control ensures stable machine operation, while automatic counting enhances efficiency and simplifies maintenance.

7. Operators can easily set parameters through the intelligent touch screen, streamlining operation and reducing manpower requirements.

8. The main components are made of stainless steel, adapting to different workshop environments and ensuring durability.