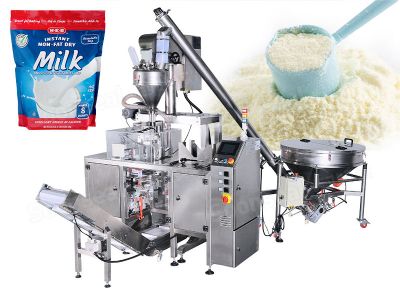

LandPack milk powder filling line is designed to provide precise and efficient packaging for a wide range of powder products. It is perfect for filling milk powder, protein powder, nutritional powder, coffee powder, medicine powder, chemical powder, meal replacement powder, and more.

Our versatile filling line supports various packaging types, including cans, tins, barrels, bottles, capsules, cartons, and stand-up pouches. Whether you prefer traditional packaging materials like glass, metal, paper, plastic, or even wood, our filling line can handle them all. We understand that different products may require different packaging materials, and we are committed to meeting your unique packaging needs.

With our Automatic High Precision Packing Project Milk Powder Filling Line, you can expect exceptional accuracy and efficiency in the packaging process. Our advanced technology ensures precise measurements and minimizes product waste, allowing you to optimize your production output and reduce costs.

| Packaging Material: |

|

|

|

|

|

|

| Milk Powder |

Milk Powder |

Milk Powder |

Milk Powder |

Milk Powder |

Milk Powder |

| Bag Style: |

|

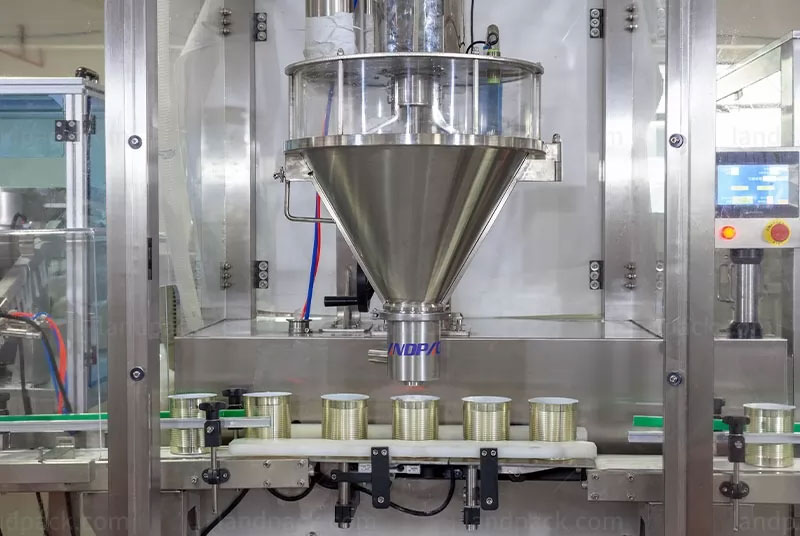

Automatic two-head Auger type metering/filling system: Our packaging line features an advanced two-head Auger type metering/filling system that ensures accurate and efficient filling. This system works seamlessly with our automatic capping machine, streamlining the packaging process.

Double star wheels for bottle/can conveying & positioning: To optimize the filling operation, our line incorporates double star wheels that facilitate smooth and precise bottle/can conveying and positioning. This feature enhances productivity and ensures consistent filling results.

Precision splitter for accurate positioning: Our conveyor is equipped with a precision splitter, enabling the intermittent movement of bottles/cans. This function ensures accurate positioning, reducing errors and maintaining product quality.

High accuracy and stability with Japan Panasonic servo motor: The transmission system of our filling machine utilizes a reliable Japan Panasonic servo motor. This high-quality motor provides exceptional accuracy and stability, guaranteeing consistent filling performance.

Automatic bottle/can positioning, lifting, and vibrating: Our filling system includes automated features such as bottle/can positioning, lifting, and vibrating. This automation ensures smooth operation and eliminates the need for manual intervention. Additionally, the system automatically stops filling when no bottle is detected or in the event of a bottle jam, enhancing safety and efficiency.

Memory modules for different products and filling weights: With 10 sets of memory modules, our line allows for easy customization and memorization of different products and their corresponding filling weights. This flexibility enables quick changeovers between various powder products, improving production efficiency.

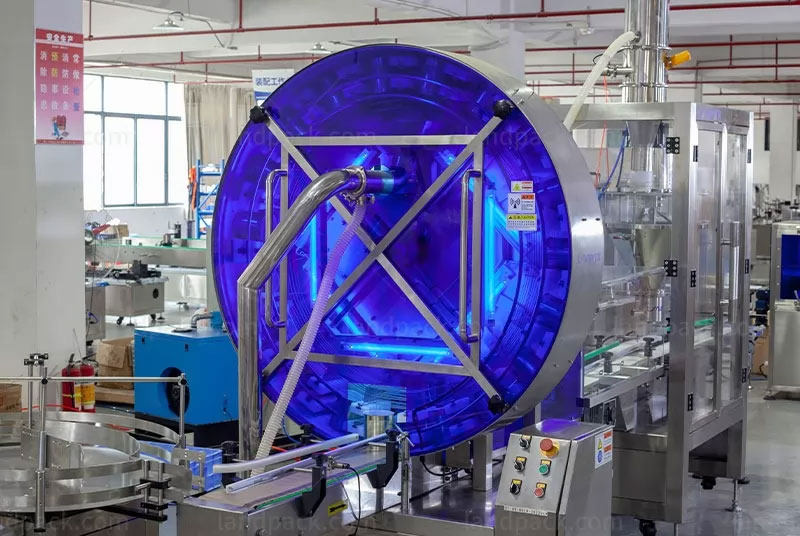

UV sterilization and purging for canned milk powder: Specifically designed for canned milk powder, protein powder, and nutrition powder, our line is equipped with UV sterilization and purging capabilities. This ensures product safety and extends the shelf life of the packaged goods.

Automated spoon dropping: Our line incorporates an automatic spoon dropping mechanism, eliminating the need for manual spoon placement. This feature enhances the convenience and efficiency of the packaging process.

Weighing filling measurement for higher precision: Our filling machine adopts a weighing filling measurement method, which provides superior accuracy compared to traditional screw measurements. This precise filling technique ensures consistent product quantities and minimizes waste.

Vacuum-sealed tank with nitrogen for extended shelf life: To enhance product preservation, our line includes a vacuum-sealed tank filled with nitrogen. This technology helps extend the shelf life of the packaged products, ensuring their freshness and quality over time.