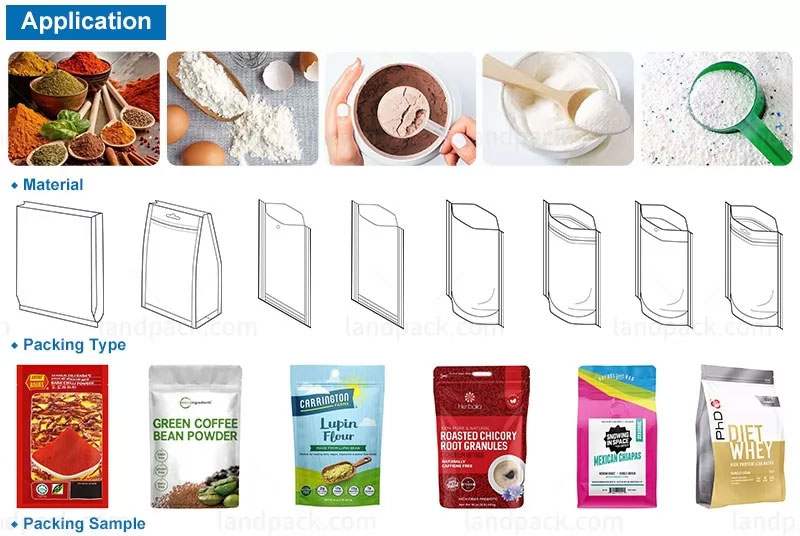

This versatile machine is perfect for efficiently packing a wide range of products such as milk powder, spices powder, coffee powder, corn flour, laundry powder, coconut powder, fruit powder, collagen protein powder, cocoa powder, chili powder, and more.

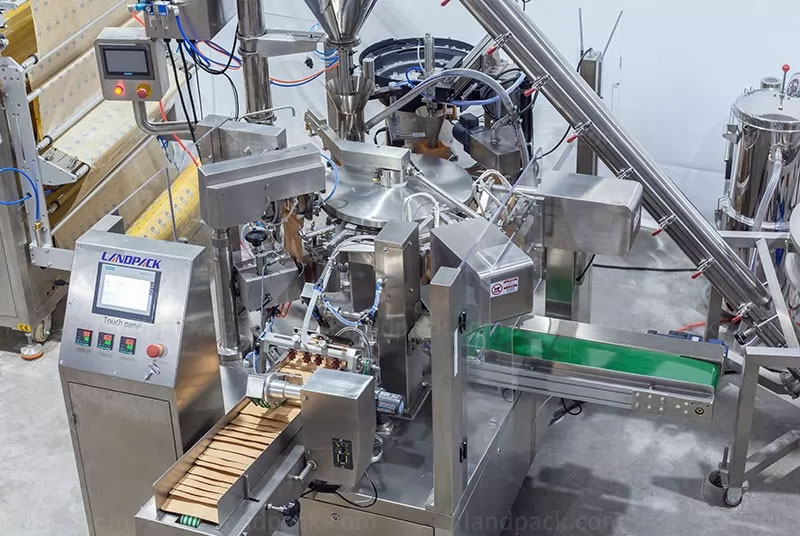

Our machine integrates multiple functions into one seamless process, including precise metering, bagging, packing, sealing, date printing, and counting. With its advanced technology and user-friendly interface, you can achieve high-speed and accurate packaging with minimal effort.

The Automatic Milk Powder Doypack Filling Sealing Machine not only ensures the quality and freshness of your powders but also enhances your productivity and efficiency. Its robust construction and reliable performance guarantee long-lasting operation and reduced downtime.

| Packaging Material: |

|

|

|

|

|

|

| Milk Powder |

Milk Powder |

Milk Powder |

Milk Powder |

Milk Powder |

Milk Powder |

| Bag Style: |

|

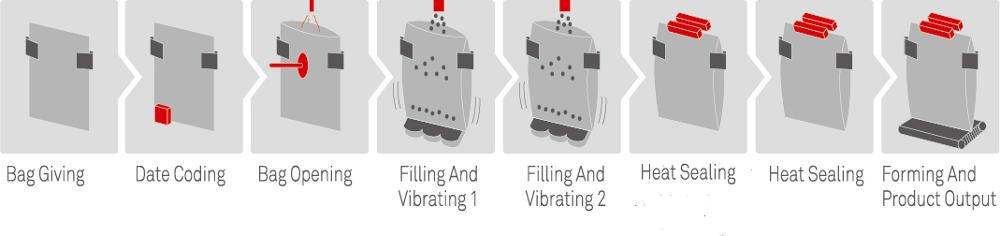

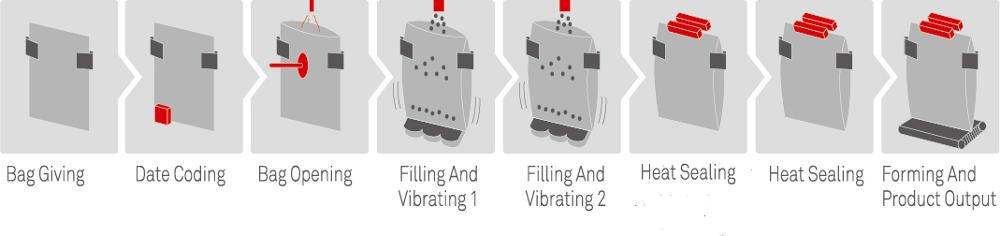

1. Bag giving--Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there is a mechanical arm with two vacuum caps will take the bag up and then transmit it to the mechanical gripper on the rotary table.

2. Date coding--According to the actual production and packaging needs, different types of coding machines are configured to print the date and batch number on the packaging bag.

3. Bag opening--While the suction cup opens the opening of the packaging bag, the air is sprayed from the upper nozzle to blow open the bottom of the packaging bag, the packaging bag support plate is inserted into the opening of the packaging bag, and the packaging bag enters the next station.

After inserting the bag support plate into the bag opening, the detection of whether there is a packaging bag and whether the opening of the bag is opened is completed. If there is no packaging bag or there is no opening to open the packaging bag, the next station will not feed.

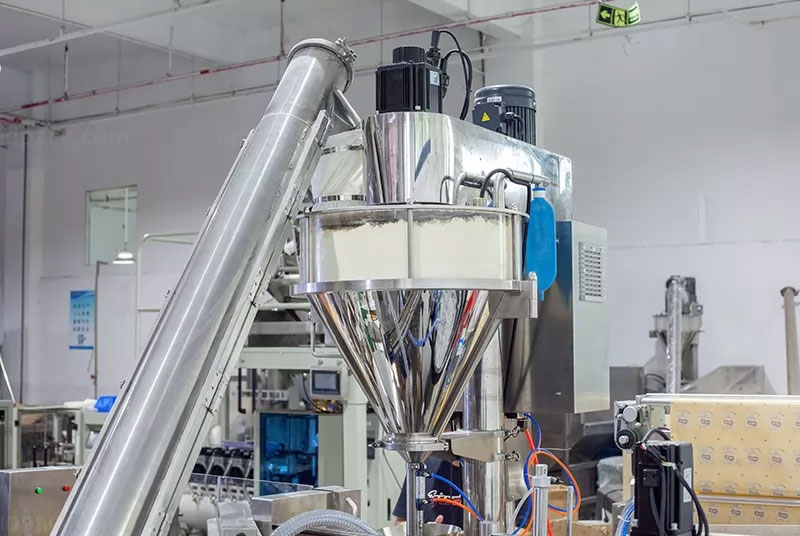

4. Filling and vibrating 1--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

5. Filling and vibrating 2--According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

6. Product settling after filling by vibrating

7. Heat sealing 1--To seal the pouch or bag mouth with a couple of heat sealing air bars, the sealing pattern you can option, net or straight lines.

8. Heat sealing 2--To make the sealing stable and preventing from wrinkling with a couple of cold presses, then output the finished production automatically.

9. Forming and product output