Automatic liquid cream bottle filling and capping labeling machine is suitable for filling liquids and pastes of any fluidity in various industries. Such as lotion, shampoo, cream, toner, emulsion, nourishing, detergent, pesticides, syrup, peanut butter, condensed milk, chocolate sauce, ketchup, shampoo, fruit juice, honey, detergent, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

|

Packaging Material & Bag Style:

|

|

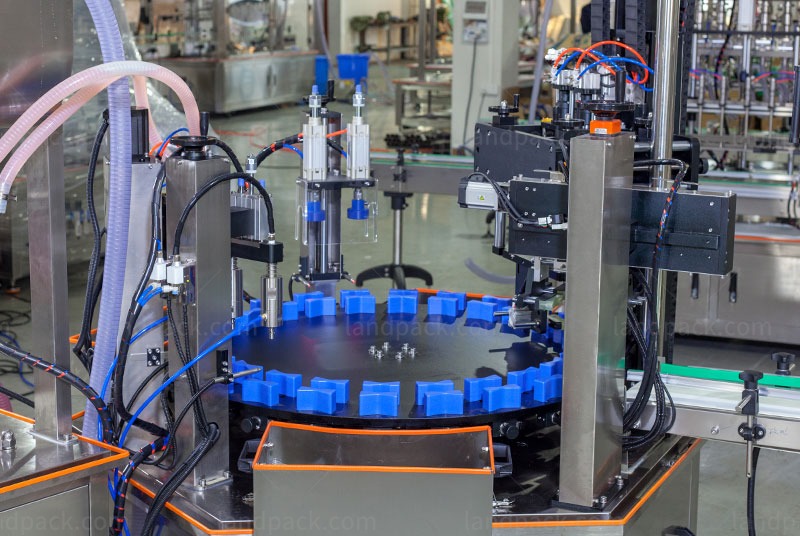

Efficient Air Cleaning and Filling: Our automatic system seamlessly integrates air cleaning, filling, inner cap inserting, and capping processes, ensuring a smooth and efficient production line.

Advanced Air Cleaning: Our system features a dedicated air cleaning mechanism that effectively removes dust and impurities, maintaining product quality and hygiene standards.

Precise Filling System: With servo motor control and rotary valve filling, our system ensures high filling accuracy. It is versatile enough to handle high foam liquids and self-suck water-type liquids, delivering consistent results.

Liquid Level Detection and Easy Adjustment: The hopper is equipped with a liquid level detection system, simplifying operation and adjustment processes, enhancing efficiency, and minimizing errors.

Adjustable Molds for Versatility: Our system offers adjustable molds to accommodate different bottle sizes, providing flexibility and versatility in production.

Screw Cap Filling System: Designed for any screw caps, our system utilizes a soft silicone material that prevents cap damage, ensuring a secure and reliable sealing process.

User-Friendly Operation: Our system is intuitively designed, allowing anyone to operate it proficiently without the need for extensive training, saving time and resources.

Five-Servo Motor Control for High Efficiency: With precise servo motor control, our system achieves high-efficiency performance, optimizing production speed and accuracy.

Comprehensive Filling Line Composition: Our filling line includes a bottle holding mechanism, air blow mechanism, servo filling mechanism, storage hopper, inner cap gland mechanism, screw capping mechanism, finished bottle pick-up mechanism, round bottle labeling machine, and inject printer for batch information, expiration dates, and production dates.

Cutting-Edge Technology and Quality Components: Our system incorporates innovative technology and utilizes high-quality components to deliver reliable performance, meeting industry standards and enabling seamless production processes.